Make your clutch facing your powerhouse— keep performing for years. That is not magic or a dream but a reality. Explore how to inspect the clutch facings in manufacturing now!

Introduction

Clutch facing are necessary parts of your vehicles. The sufficient friction eliminates the vibrations during gear changing and ensures a smooth driving experience.

What is most crucial is to get quality. And it is possible only if you get the best chance to test the quality. Are you ready to explore the first guide on the clutch-facing inspection in the factory? Let's go through this in detail.

Why is Clutch facing inspection important?

Think for a moment about the clutch facings. They help in the seamless driving experience and provide the ultimate safety.

Many more reasons make them a differentiated choice. Here are those reasons.

Safety purposes

A faulty clutch is a massive problem. It can bring in significant issues such as loss of power transmission. In high traffic conditions, it can cause accidents.

So, how does clutch facing help?

It is quite impactful in transferring the power in the vehicles—risks of failure decrease, leading to better safety during driving.

Performance

What is the ultimate goal of the clutch facing? It is to transmit the power. So, get a clutch facing with high friction power that ensures smooth operations. Check its performance:

- Go for the visual inspection and check for any structural and crack abnormalities.

- Apply tests to check the compatibility with your vehicles.

- Confirm the material composition and quality of the clutch facings.

- Maintain the high efficiency of your clutch facings.

Now, you are good to hunt down the quality facings.

Durability

What if you have purchased the clutch facing again and again? That feels like a real headache. But you can avoid it by using the proper techniques. For example, go for the best quality. Inspection plays out in this process

Extending the life of the clutch facing is possible with regular inspection. Check for the scratch marks. Maintain your clutch facings and get them repaired by the experts. Effective maintenance can breathe a new life every time, giving them a better chance with ultimate durability.

Cost efficiency

Don't go for multiple investments for a single clutch facing. Instead, you can do the maintenance and let your facings be there for years.

Tackle the major issues while monitoring your driving and vehicle conditions. Get the compatible solutions. In the long run, you'll invest less and drain more benefits from your clutch facings. Moreover, the diversity of applications also engages your facings in multiple vehicles.

Customer satisfaction

There is a general rule.

Customers opt for the best.

That is true even in the case of the clutch facing. You can test the materials and durability of your facings. Also, consider the thermal resistance and strength for an extended life span.

Devise a revolutionary clutch facing that exceeds your customer's expectations. As an individual seller or brand, keep consumers' satisfaction 100%. Bring in a massive wave of loyal customers.

How does factory inspect the clutch facing?

It is a good question— how will you proceed with the clutch-facing testing? Start from the visual inspection and go deep until you check the friction coefficient and efficiency.

Visual inspection

First of all, set your eyes on the clutch facings. See how they look. Check for any visible cracks, scratches, or chips. Don't overlook the material quality and external finish to check the clutch facing.

Material composition

Which material have you used? Clutch facings can comprise various materials such as:

- Metallic

- Organic

- Ceramic

Now, what is the composition of your clutch facing? Go for the spectrometry to check the overall ratio and composition of different materials. Perform the hardness testing as well. Confirm it is within the required limits.

Surface inspection

Whether metallic or ceramic clutch facings, you have to inspect the surface finish. Check for any cracks and eliminate them promptly. Also, monitor the smoothness of the surface and indicate any deviations from the flat surface. A smooth surface offers a smooth transmission.

Check the dimensions and measure them. Dimension measurements include:

- Outer diameter

- Inner diameter

- Thickness

The precision of thickness of a clutch facing must be within 0.1 millimeters. Validate the measurements and precision!!

Mechanical testing

Do you want the longevity of your clutch facing? Clutch facings have to undergo tensile stress. Therefore, go for the wear and tear resistance.

There is a secret to testing the mechanical features:

- Apply mechanical stress and check the strength.

- Check the wear resistance of the material.

Have you done all of these? Great. Measure and compare the values and know how much strength is the strength. Go for the high-strength material that sustains stress and provides a long life.

Thermal testing

The burning of petrol or diesel raises the temperature of the engine. If the material loses its integrity with the high temperature, what results? It is simply a low-quality material that is not good for the engine.

So, what to do? When manufacturing the clutch facings, check the thermal resistance. For example, implement the 400°C of temperature to the carbon clutch facings. Does it survive? If yes, it can be suitable for your engine.

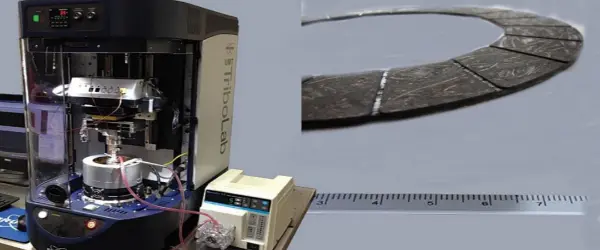

Friction Testing

The friction coefficient is necessary for the smooth power transmission from the engine to the transmission system. Check the friction of each material.

If you have purchased the organic maal, check the friction. Keep a suitable range of friction during manufacturing. It must offer sufficient power to transfer power smoothly.

Conclusion

When using the clutch facing, one thing is necessary — Quality. It gives a life. So, find the clutch-facing suppliers who are emblems for quality. For any questions about the quality and inspection of clutch linings, you can contact Kukauto experts, who have rich experience in producing flawless clutch facing. Our high-end facings bring in the best driving experience and nurture durability.

FAQs

- What characteristics must a clutch facing have?

A clutch facing must have various useful features. These include:

- A high friction coefficient ensures smooth power transmission.

- Heat resistance because of high temperature in the vehicles.

- High wear resistance to minimize your investment and increase the lifespan of facings.

- High tensile strength to survive shear stress.

- What are popular materials used in clutch-facing manufacturing?

Clutch-facing can comprise numerous materials. Each material provides a different feature.

- Organic materials such as aramid fibers and Kevlar.

- Glass fiber

- Ceramic materials

- Carbon fiber

- Is clutch inspection necessary?

Yes. 100%. Clutch inspection provides a detailed report about the quality. It can affect the material’s performance and bestows a long life with outclass power transmission. Get experts and check your clutch facings.