- +86 136 6539 1003

- kukauto@163.com

- Mon - Fri: 9:00 - 17:00

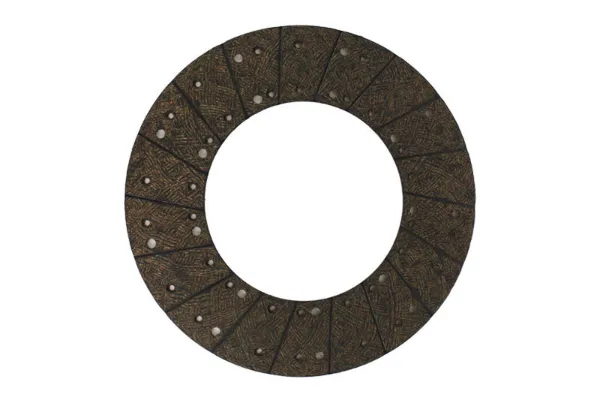

Non-asbestos Clutch Facing For Vehicles and Machines

Kukauto is a clutch-facing manufacturer in China. We have built a standard production process with a strict quality inspection system.

The material we choose is non-asbestos environmentally friendly material. Our clutch-facings are widely applied in vehicles and machines.

Top-level Clutch Facings for Automobiles

Kukauto produces a wide range of quality-guaranteed, stable friction coefficient clutch linings with a long life span and low cost that exceeds the highest standards in the industry.

Clutch Facing K209

Clutch Facing Model K209 is made of glass fiber woven with copper wires, it provides high wear resistance, stable friction coefficient, and good heat transfer characteristics. The material is a medium friction material and is economical for customers.

Clutch Facing K8106

The Clutch Facing Model K8106 is made of non-metallic composite yarn, with a lot of aramid fiber included. It is an alternative for sintered metal materials clutch facing, it offers non-abrasive to the counter material, high surface pressure, and noiseless when working.

Clutch lining K8209

The Clutch Lining Model K8209 is updated in the formula based on the model K209. The copper wire is tightly spread on the surface. It has a higher friction coefficient and thermal conductivity. Its excellent performance performs very well on most of the automobiles.

clutch lining K8008

The Clutch Lining Model K8008 is made of carbon fiber, with a lot of composite yarn and glass fiber. It is an alternative for sintered metal materials clutch facing, it resists high energy inputs and is perfectly suitable for both dry and wet clutch systems.

Special Features

Free Asbestos

Our products are free of asbestos, asbestos is banned from use in many industries because it causes diseases such as mesothelioma, lung cancer, and asbestosis. We regard safety as the first position.

Stable friction coefficient

After testing at 300 °C and 0.49 Mpa pressure force, our clutch facing keeps the friction coefficient at 0.39, and the wear rate is 0.3, verifying our products with a stable friction coefficient.

Temperature resistance

The clutch linings we made use many coppers, which are excellent in conducting high heat, so when the vehicles cause high temperatures, our clutch linings can transfer the heat and ensure stable running.

Good precision

The thickness tolerance of our clutch facing is 0.1mm, we measure the dimensions before shipment and make sure all the clutch linings are with good precision and high performance.

Specifications

| Model | Material | Friction Coefficient | Wear Rate | Application |

|---|---|---|---|---|

| K209 | Glass fiber, copper wires | 0.2-0.35 | 0.2-0.34 | Motorcycle, Minicar, Passenger car |

| K8106 | Composite yarn, cooper wires | 0.39-0.46 | 0.14-0.3 | Bus, SUV, Heavy-duty truck |

| K8209 | Glass fiber, copper wires | 0.25-0.38 | 0.18-0.32 | Passenger car, SUV,Pickup |

| K8008 | Carbon fiber, copper wires | 0.35-0.45 | 0.12-0.26 | Heavy-duty truck, Mine dumping truck |

Why Choose Clutch Facing From Kukauto

Kukauto is a world-class company with efficient business organization, standardized production processes, and advanced management system. We bend ourself to design, manufacture, deliver the quality clutch facings according to each customer’s requirement.

- IATF 16949 certificated: We pay much attention to the quality. At the beginning of the establishment, we devote Kukauo to the most trusted brand in the world.

- 200+ Patented formulas: Through continuous research and development, we have developed more than 200 patented formulas to meet the needs of different vehicles

- Full inspection: In addition to third-party testing, we provide comprehensive inspecting before shipment to ensure that every piece of clutch facings delivered to customers are qualified.

Customized Clutch Linings For Specific Needs

We can customize the clutch linings according to the customer’s requirements, such as dimensions, colors, material, and special functions.

We provide multiple materials for your selection, the materials include glass fiber, organic, composite yarn, ceramic, and carbon fiber.

Clutch Facing Applications

The clutch facings are widely applied in many types of vehicles as an important component in the clutch system, their frictional function transfers the power from the engine seamlessly and smoothly, the vehicle types include:

- Minicar

- Passenger Car

- SUV

- Bus

- Heavy-duty Truck

- Mine Dumping Truck

- Construction Machinery

Quick and Safe Shipment

- In cooperation with the world’s leading logistics companies, we provide multiple transportation modes according to the size of the order, such as Express, Air, Sea, and Railway transportation. We will choose the most appropriate way to make sure the goods are delivered to you on time at the most reasonable price.

- The customized package with a logo is available, we value your brand and provide the waterproof and enhanced package to ensure the items reach to you with high performance.

How do we guarantee the quality of the clutch linings?

We regard quality as the cornerstone of business survival. In order to make every product have long-lasting and durable characteristics, we have established a standardized production process and quality inspection system. From the selection of materials to the production process, we continuously optimize and implement comprehensive inspections before shipment. Let you buy with confidence.

Manufacturing process

We optimize the manufacturing process and create standardized operating procedures to shorten the production cycle and increase production efficiency

Materials Selection

According to the characteristics of different materials, we choose asbestos-free and environmentally friendly materials as the main raw materials and produce the clutch facings with a stable coefficient of friction, high-temperature resistance, and low wear rates, which can be suitable for different car models.

Transportation:

We try to choose direct routes to avoid damage to the goods. Transportation packaging is reinforced, waterproof treatment, to prevent all risks occurring during transportation.

Full Inspection

We provide comprehensive inspection before delivery, including dimension measurement, appearance defects, edge neatness, and coefficient of friction testing. The defective rate is controlled within 1%.

Packing Protection:

Packing materials are all waterproof to prevent moisture and damage during transportation. The outer box is made of a 5-layer reinforced carton to ensure the product’s safety without any damage during transportation.

More Than Just a clutch facing Manufacturer

Our prompt support, adherence to high standards, customer-centric solutions, and sound advice underpins our growing reputation as we always strive to provide a variety of optimal solutions to help your business grow.

OEM Support

We have rich OEM experience for more than 12 years and become the appointed OEM of many famous companies, such as SINOTRUK, SHACMAN, TONLY, XCMG, LGMG, SANY, etc. We are familiar with the requirements of each OEM and produce strictly according to their requirements.

Long Warranty

We consider warranty as a value-added service for after-sales service and absolute trust in the quality of our products, therefore we offer a long-term warranty of 30,000Km for non-special purpose vehicles under normal use. If you have special requirements, please contact our experts.

Environment First

Kukauto is always dedicated to supplying the clutch facing with environmental material, free of asbestos. During production, Kukauto tries to avoid any damage to the environment, for example, we install a dust recovery unit in the workshop to recover the dust and exhaust gases generated during the production process. Pollutants are controlled completely below national standards.

Worker Protection

We respect every worker’s opinion and effectively protect every employee’s rights. In the production process, we set up standardized procedures for compliance and safety, and let every employee implement them. We equip each employee with dust masks, work safety clothing, and safety shoes to ensure the safety of each employee.

Frequently Asked Questions

We have compiled the most frequently asked questions about our clutch facings here for your convenience, but please feel free to contact us if you have any additional questions.

What is a clutch facing?

The clutch facing, also know as clutch lining, is a circular plate looks like a CD, which is made from friction materials. It is installed in the clutch driven disc to transmit the engine’s power.

Learn more about clutch facing: What Is Clutch Facing? The Ultimate Guide

How can I get a quote for the clutch lining?

Click here to contact customer service now for a detail and precise quotation, include specification such as images, dimensions, materials, model, delivery time, payment terms and so on.

What is your MOQ for the order?

For standard model of the clutch facing, the MOQ is lower than 100 pieces, and for customized model, we should analysis the formula and discuss it accordingly.

What is the turnaround time on my order?

It takes us around 15 to 20 business days to produce the standard model clutch facing. On the other note, the transit time will take 10 to 20 business days. Reach us online for your custom and bulk orders so we can explain the actual turnaround time based on the specific details of your order.

What is the difference between dry clutch facing and wet clutch facing?

The dry clutch facing is installed on the dry clutch system and wet clutch facing is installed on the wet clutch system. The materials are different. The dry clutch facing is usually made from glass fiber, organic fiber, ceramic and carbon fiber. The wet clutch facing is made from sintered bronze/ iron, paper, graphite and steel.

Can I get a sample before place the order?

Surely! You can always request a sample before place the bulk order. Sample time usually will take 2-3 days, depends on the specifications you need.

Request a sample now!

Can you produce the clutch facing in specific dimensions?

Yes, we can make the clutch facing according to specific dimensions to meet specific needs. The tolerance of dimension is less than 0.1mm.

What is your warranty for your clutch facings?

Quality is our cornerstone. All of our clutch facings are provided with a 30,000Km warranty.

Click and learn more about our quality now.

Want more Details?

Send your Idea Now!

If you have any questions or ideas, please share them with us.

Our specialist will get you covered and make your idea come true!

Let’s work together to do something different!