I have read tons of guides. But no use! I checked tons of materials. But less likely, some of them were worth using in the clutch facing.

Do you know where the real DEAL lies?

It is the material's strength and durability. Every single person wants to get the optimal performance of clutch facing.

In clutch facing, glass fiber and composite yarns are popularly used materials. But tell me…

Who has got the most strength?

Let's find out in this guide the difference between glass fiber and composite yarn.

What is glass fiber?

Glass has a history of centuries. Going back to 1713, people have used glass since then. Glass fiber has many applications in the industrial fields.

But what is glass fiber? Is it the same as the glass?

Glass fiber comprises fine fibers of the glass. The ultimate goal of producing fine fibers is their strength and lower investment costs. It is a highly reinforced material that has a very less brittle nature.

Therefore, we use it in the clutch facing and industrial machines to produce various components.

What is composite yarn?

You might have HEARD of cotton, silk, or wool. Am I right?

Composite refers to the COMBINATION of two or more materials. It can be either natural or synthetic. Aramid is the BEST EXAMPLE of synthetic composite material.

The natural composite material is the yarn made with cotton, wool, or silk. But composite yarn can be synthetic. An excellent example is the combination of synthetic fibers like polyester, nylon, and spandex.

Manufacturers produce composite yarn. It matches required features like strength, elasticity, and water resistance.

Glass Fiber vs. Composite Yarn Material: What are the differences?

In clutch facing, glass fiber and composite yarn play a crucial role.

Hmm…..Do they both share the same features?..... Which one is better?

Are you searching for the perfect answer? I have simplified it here. Let's go through a detailed comparison of glass fiber and composite yarn.

- Material

Most of the time, when buying anything, I first look at the type of material. It determines the strength and features such as durability, malleability, and power.

In glass fiber, the manufacturing material is silica or sand. Different industrial methods melt the silica/sand. The final composition is excellent glass fiber.

In contrast, composite yarn comprises different materials based on what you choose. If you lean toward natural materials, cotton, and silk composite is an ideal choice. For synthetic ones, you should try nylon or polyester.

So, who is better? Let's know more features before we land a final decision.

- Tensile Strength

Tensile strength measures the force applied to the material to elongate. And guess who's got more power?

Apparently, it looks like glass fiber. But it is 100% wrong. The composite yarn has the maximum tensile strength.

Winner: It is the Composite yarn this time.

- Elasticity

Elasticity refers to the measurement of the resistance to deformation. In simple words, we can say which material is stiffer. For the clutch facing, it is VERY IMPORTANT to have enough resistance to the deformation when friction occurs.

Glass fiber has more elastic strength compared to composite yarn. Flexible power makes the glass a robust material in the clutch.

Winner: It is Glass fiber this time.

- Temperature Resistance

Temperature resistance is another parameter to measure the withstanding power material. How much temperature can it withstand?

If we look at the yarn and glass fiber, it is clear that glass fiber has more strength. It needs more FORCE to either break it or more temperature to melt it efficiently. It makes the glass fiber suitable for use in the clutch facing.

Winner: Glass fiber is the winner this time.

- Tear Resistance

Tear resistance is the brittle feature of a material. The more solid the material is, there is higher chance of tearing apart into the piece.

In clutch facing, we can take a rough idea of the tear resistance.

Glass is more brittle, and so is the glass fiber. It can't sustain the tear stress and breaks into pieces quickly. Compared to it, you can apply as much force on the composite material; it does not break easily. It takes very power because of a combination of fine cotton fibers or silk.

Winner: Composite yarn is the winner this time.

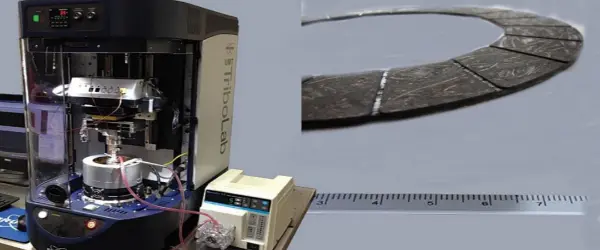

- Abrasion Resistance

Abrasion is paramount to the material. It refers to friction resistance. The more friction power means high suitability for the clutch.

We can't decide what has more abrasion resistance, glass or composite yarn. It depends on the manufacturing quality and thickness of the fiber. If the glass fiber comprises the highest quality, it has more abrasion. The same goes true for composite yarn.

If the thickness is more, the material is suitable for the clutch facing to endure the hard seasons. Therefore, the manufacturing quality and thickness are the deciding factors. However, glass fiber is more abrasion resistance compared to composite yarn if it has a high thickness.

Apart from the main materials of the framework, other factors have an impact on the features of the clutch facing.

For example:

- Synthetic Resin

- Synthetic Rubber

- Copper

- Pigments

They also determine and enhance the features of clutch facing.

Have we got the best material for clutch facing?

The clutch facing is always under friction between the engine and transmission. It facilitates smooth functioning.

The good thing about glass fiber and composite yarn is, both are very prevalent choices. Some factors can't decide what is the best material. However, it largely depends on your engine's power and torque. For example, a motorcycle clutch differs from a car, except the primary purpose is to transmit power and work smoothly.

You have to choose wisely what is best for your clutch.

EndNote

Is it hard for you to choose glass fiber or composite yarn? No MORE! Just list your requirements and the quest for the best material. Whenever buying a clutch-facing glass fiber or composite yarn, you should determine the quality and friction resistance.

Are you interested in buying some quality pieces?

KUKAUTO got you. We are a professional manufacturer of clutch and related materials. Our high-quality products are going to be your PARTNER everywhere for extended periods. Check out our collections!