Have you ever observed a clutch facing? If you see a clutch-facing, some copper wires are on the surface. Maybe multiple questions have flashed through your mind. For example, why should we even use copper in the permukaan kopling?

Does copper have any role in this process?

Ingin tahu peran tembaga pada permukaan kopling? Jika ya, Anda adalah pemandu yang tepat. Izinkan saya menjelaskan peran tembaga dalam kopling.

What is Copper metal? Can we use it in the Clutch Facing?

Copper is an element with an ATOMIC number of 29. Due to its high malleability and ductility, it is widely used in manufacturing wires, clutch facings, and machines.

There are many forms of copper. Red copper is the pure form. We call it the RED COPPER due to its purple-red. Its applications are often electrical materials, roofing, and industrial machinery.

Brass is an alloy of copper and zinc. Making an alloy increases the strength and hardness of the metal. Its applications include locks, hinges, bearings, electrical plugs, and valves.

So, can we use it in the clutch facing?

Yes, we do use the COPPER in the clutch facing. It is because of high-temperature resistance and coefficient of friction. It optimizes the performance during the power transmission from the engine to the transmission system.

Why add copper in clutch facings?

Copper is an excellent material for clutch facings or clutch linings. No wonders in that!

Here are some peculiar features that make copper an EXCELLENT material for clutch systems.

- High Copper Coefficient of friction

The ultimate goal of the clutch facing is to decrease the torsional vibrations produced during power transmission. And friction is quite essential in that case. Therefore, you need to settle on a material that has a copper coefficient of friction.

Copper has a high coefficient of friction to smoothen the power transmission. There is no risk of developing severe vibrations or decreasing performance. Hence copper is a suitable material for clutch facings.

- Thermal Conductivity

Thermal conductivity refers to the ability of heat transference. Some metals are bad conductors, while others might be good conductors.

Guess, is COPPER a good heat conductor?

Yes, copper is one of the top metals with high thermal conductivity. It is third on the RANK after the diamond and silver.

In the engine, heat production is a natural phenomenon. A good metal can help dissipate heat and maintain the automobile's braking system.

That is what copper does. It helps in decreasing the net thermal stress on the braking system. That is why copper plays an essential role in the clutching system in automobiles.

- High-Temperature Resistance

Copper has a high melting and boiling point. Its melting point is 1085 degrees Celsius. That means copper is going to work in the clutching system perfectly.

Its coefficient of friction varies slightly when up to 175 degrees Celsius. After that, it decreases up to 250 degrees Celsius. After that, an exponential decrease occurs.

Temperature is critical in automobiles or machines. Automobiles work on the oil ignition that increases the temperature. In that case, you need the material that copes with the high-temperature conditions.

What else can be better than copper?

You can expect a better performance from the copper metal.

- Resistance to Applied stress

In automobiles, stress and strain are the typical scenarios. It is due to the high weight and heavy engines used. Moreover, in changing gears, there is applied stress on the clutch.

As far as copper is concerned, it shows high resistance to the applied stress. That is a great feature. It protects the clutching system from performance decrease due to stress. So, clutch facings have copper material.

- Kekerasan

Red copper does not have a high hardness. However, its alloys, like the brass, have a high hardness making its place in many real-life applications. You can get an idea of HARDNESS.

The hardness of copper is like a double-edged sword. From one point, it provides wear resistance. On the other hand, it can break the parts connected to it.

Wear resistance is quite crucial in automobiles. It does not decrease the performance of the engine. Even it makes the system work for extended periods without impacting the performance.

There is one con. Hardness can break the parts connected to it. You must know it before using the copper in your clutch facings.

- Rotating speed

In automobiles, there is high RPM when driving at a higher speed. Clutch facing is crucial for engaging and disengaging the engine from the transmission system at such a high speed. Choosing a material that enables clutching at such a speed is a good idea.

Copper helps here. It is because of a slight change in the coefficient of friction. Easy engagement and disengagement are possible due to copper at a higher speed. Therefore, copper is popular as a material for clutch facings.

Is clutch facing better to add more copper?

Adding more copper increases the hardness. It affects the power transmission in the engine and even breaks the parts connected to it. You need to use copper according to the torque and power of the engine to make the BEST combination with a smooth transmission.

Here's A recap of features that improve clutch facing by adding more copper.

- It is a good conductor of heat. A combination of high pressure and rubbing speed ensures heat conductance.

- Oil ignition might raise the temperature. Copper resists and optimizes performance.

- Hardness increases durability.

- A high coefficient of friction favors the use of copper.

FAQ

- Is it possible not to use copper in the clutch facing?

Yes, it is possible not to use copper in the clutch facing. But copper has endless features making it a good choice for the clutch facing. Due to high thermal conductivity and temperature resistance, copper becomes a good choice for use in the clutch facing.

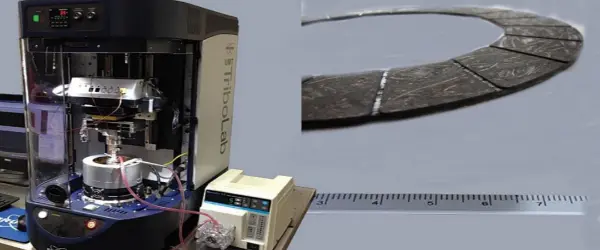

2. How to recognize adding copper to the clutch lining?

If you want to recognize the use of copper in the clutch lining, there are three ways to check it:

- Look at the color: If the surface of the clutch lining has yellow wires, it must be added copper.

- Touch the surface: When you touch the surface of the clutch lining, the surface is rough, the metal should be copper.

- Heat the clutch lining: When you heat the clutch lining, you can feel the high temperature in the wires, it maybe adds copper.

3. What percentage of copper do we usually add in the clutch facing?

In the menghadap kopling, copper is added according to the engine power and torque. The percentage varies from 30-65% in the manufacturing process. Some other materials, such as iron or graphite, are added too.

EndNote

To make the story short, Copper helps in clutching. It can provide better power transmission in automobiles. Keep the engine performance high. And be durable for extended periods.

You should consider the torque and power transmission factors when adding copper to the clutch-facing production.